Relationship Between Resistance Coefficient and Valve Opening Position

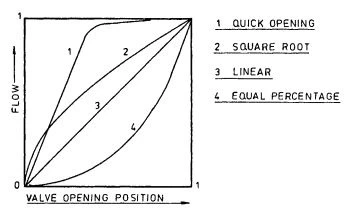

The relationship between fractional valve opening position and relative flow through the valve is denoted as flow characteristic. When flow at all valve opening positions is taken at constant inlet pressure ion, the flow characteristic thus determined is referred to as inherent. Figure 2-9 shows such inherent flow characteristics that are typical for flow control valves.

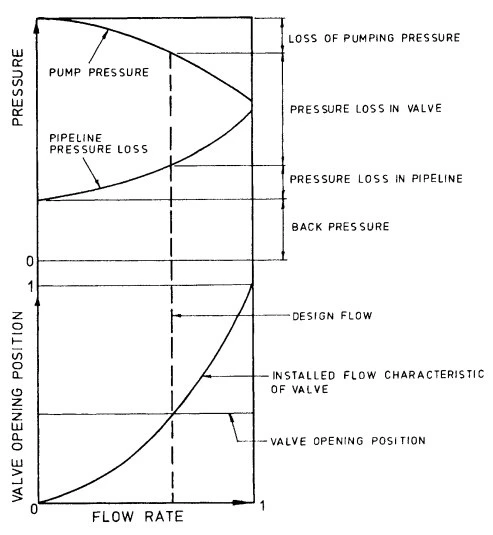

In the most practical applications, however, the pressure loss through the valve varies with valve opening position. This is illustrated in Figure 2-10 for a flow system incorporating a pump. The upper portion of the figure represents the pump characteristic, displaying flow against pump pressure, and the system characteristic, displaying flow against pipeline pressure loss. The lower portion of the figure shows the flow rate against valve opening position. The latter characteristic is referred to as the installed valve flow characteristic and is unique for each valve installation. When the valve has been opened further to increase the flow rate, the pressure at the inlet of the valve decreases, as shown in Figure 2-10. The required rate of valve opening is, therefore, higher in this case than indicated by the inherent flow characteristic.

Figure 2-9. Inherent Flow Characteristics of Valves.

Figure 2-10. Relationship Between Flow Rate, Valve Opening Position, and

Pressure Loss in a Pumping system.

If the pump and system characteristic shows that the valve has to absorb a high- pressure drop, the valve should be sized so that the required pressure drop does not occur near the closed position, since this will promote damage to the seatings from the flowing fluid. This consideration leads frequently to a valve size smaller than the adjoining pipe.