Locked Open And Locked Closed for Valve

LOCKED OPEN AND LOCKED CLOSED

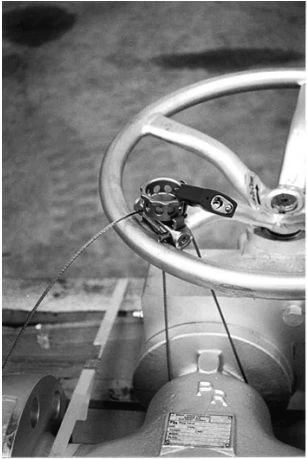

As the item that had to be closed is a valve in one location, the reason for having a keyless method of opening was not necessary and the wire was changed to a chain and closed with a padlock. (see Figure 10-1 and Figure 10-2). To change the function of a valve from open to closed or vice versa, can only be done by authorized operators, hence the terminology “key personnel.” To this day this is the preferred method of securing valves to be locked open or locked closed. This method prevents the unintentional operation of important valves. Indeed on many of today’s projects, valves are often specified with a facility to add a locking device as part of the scope of supply. This could be either a cleat located on the body of the valve, through which a chain or a D-lock can be placed, or a plate with a drilled hole on a ball or plug valve. This method is identified on P&ID drawings and associated plant documentation as LC (locked closed) or LO (locked open).

Figure 10-1. Wire on Gearbox with Independent Padlock Butt Weld.