Double Block and Bleed Ball Valve

Double block and bleed ball valves saves space, weight, and labor costs where possible, while still retaining the original function of the valve.

An Introduction to Double Block and Bleed Ball Valves

The increased activity in the offshore sector of the energy industry has led to additional factors that have to be taken into consideration when designing piping systems. Space in these offshore locations is always at a premium and the design of piping systems and their associated components must therefore be more compact. There are structural constraints that are also very important, such as to keep the structure as light as possible, and there are obvious benefits from making components smaller and lighter. Construction labor in offshore locations is also very expensive and any reduction in installation manpower is also beneficial.

The above situation has led to the modification of the patterns of valve components to incorporate savings in space, weight, and labor costs where possible, while still retaining the original function of the valve. Initially these modifications have meant that there is a cost impact, however when installation costs are reduced, the final costs are then comparable with the multi-component option used in the past.

Double Block and Bleed Isolatio n Philosophy

Process isolation philosophy has become more complex as safety issues have to be addressed and the requirement for double block and bleed isolation has become more commonly used, especially in offshore loca- tions. Double block and bleed isolation requires two in-line isolation valves and a bleed valve, used to drain or vent trapped uid between the two closure elements. Double block and bleed valves are special components, however there are now several manufacturers of this type of valve. These double block and bleed ball valves have been used very successfully in the offshore sector of the energy industry and their numerous benefits have been realized there not only for new builds, but also for existing plants where they have been retrofitted.

When a process calls for a double block and bleed isolation philosophy, these valves are used for two functions:

1. Instrument double block and bleed (2" and below)—for pressure connections, chemical injection, sampling, vents and drains, etc.

2. In-line double block and bleed (2" and above)—for process isolation.

Instrument Double Block and Bleed B all Valves

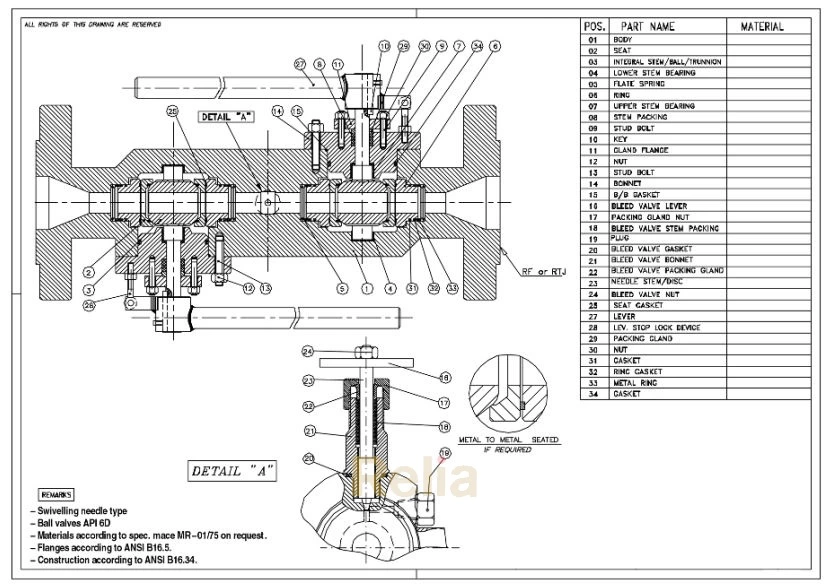

These small bore compact double block and bleed valves (Figures 9-1 a and 9-1 b) are generally used to isolate instrumentation such as pressure indicators (PIs) and level gauges (LGs) and they come in a variety of combinations.

The two isolating valves are usually of a quarter-turn ball type, with either soft or metal-metal seats depending on the design conditions of the process fluid. The smaller usually 3/4" or 1/2" bleed valve can be a globe, needle or in some cases a ball type design. The body can be of a one piece or a split type and the ball can be either a floating type or a trunnion type design in the high-pressure classes.

The end connections can be anged both ends, or anged one end and threaded the other end to receive the instrument gauge. Other end connections such as clamp type are available if specified by the purchaser.

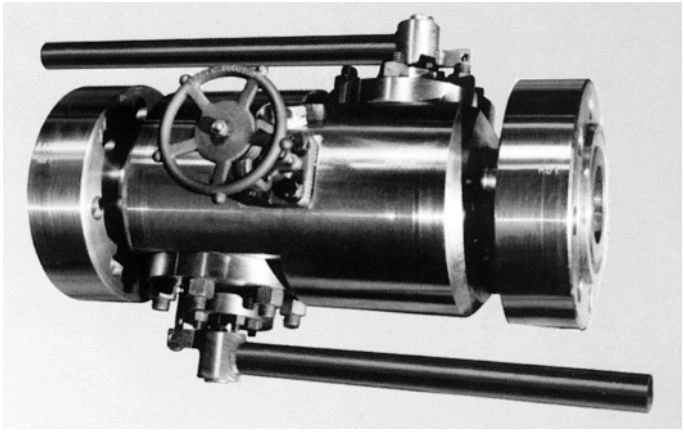

Figure 9-1. (a) Double Block and Bleed Top Entry.

Figure 9-1. (b) Double Block and Bleed Top Entry General Arrangement.

These compact valves can also be used for injecting chemicals or sampling process uid by adding straight tubing onto the bore of the ange face. When assembled onto a mating angethis quill enters into the process ow and chemicals can be introduced through the valve and then the tube, which is in the process ow. An additional in-line poppet type check valve is incorporated in the compact valve to prevent reverse ow and process uid contaminating the chemical source. For sampling the reverse is applied and samples can be removed from the process uid, via the quill, through the open in-line valves and then collected in a sample bottle, which can betaken away for analysis.

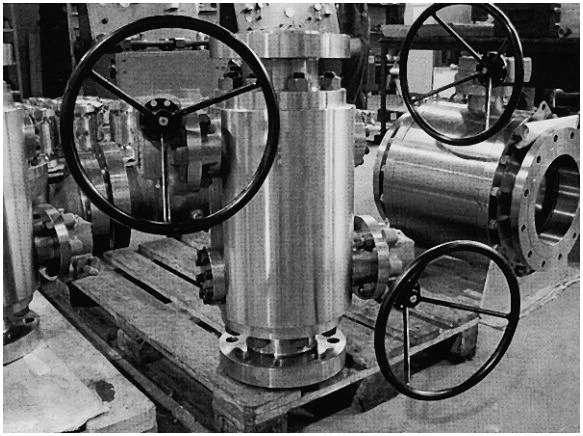

Figure 9-2. (a) In-Line 4" 900 Class Double Block and Bleed Ball Valve Trunnion Mounted Side Entry.

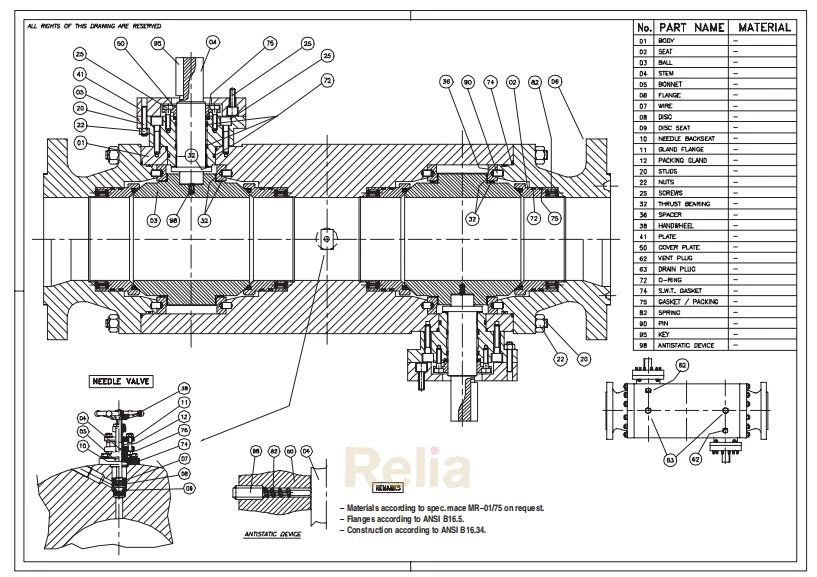

Figure 9-2. (b) General Arrangement Drawing of In-Line Double Block and Bleed.

Figure 9-2. (b) General Arrangement Drawing of In-Line Double Block and Bleed.

In-Line Double Block and Bleed Ba ll Valves

These (see Figures 9-2a and 9-2b) are larger in size, usually 2" and above, and they are located in the primary process stream. These compact valves can be supplied in a similar number of end connections as the smaller instrument double block and bleed versions. Because of their size, a threaded connection will rarely if ever be used, however butt-weld end connections are an option that is available, along with clamp type end connections.

These in-line double block and bleed valves are available up to around 8" and pressure ratings up to and including ASME 2500 lb. Availability will depend on the manufacturers and their capabilities. In very special cases some companies are in a position to create special patterns and construct these valves in larger sizes.

In-line double block and bleed ball valves are expensive; however, when you consider the cost of the individual valves, the interconnecting pipework, and the fabrication, the two costs are comparable in sizes up to 8". The double block and bleed valve is a very heavy component and in the larger sizes it will require lifting studies if the valve is to be removed for maintenance.