Valve Selection Criteria

The method by which the closure mber regulates the flow and the configuration of the flow path through the valve impart a certain flow characteristic to the valve, which is taken into account when selecting a valve for a given flow-regulating duty.

Valves for Stopping and Starting Flow

These valves are normally selected for low flow resistance and a straight- through flow passage. Such valves are slide valves, rotary valves, and flex-body valves. Closing-down valves offer by their tortuous flow pas- sage a higher flow resistance than other valves and are therefore less frequently used for this purpose. However, if the higher flow resistance can be accepted—as is frequently the case—closing-down valves may likewise be used for this duty.

Valves for Controlling Flow Rate

These are selected for easy adjustment of the flow rate. Closing-down valves lend thselves for this duty because of the directly proportional relationship between the size of the seat opening and the travel of the closure mber. Rotary valves and flex-body valves also offer good throt- tling control, but normally only over a restricted valve-opening range.

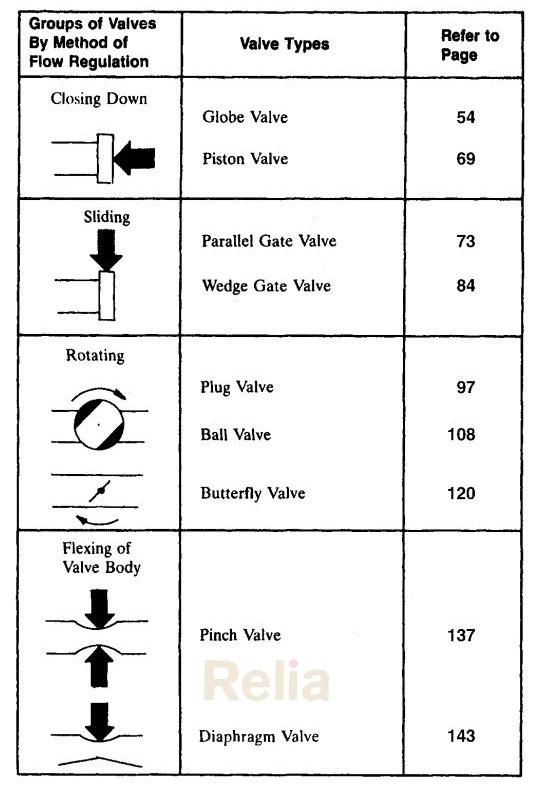

Figure 3-1. Principal Types of Valves Grouped According to the Method of Flow Regulation.

Gate valves, in which a circular disc travels across a circular seat open- ing, achieve good flow control only near the closed valve position and are therefore not normally used for this duty.

Valves for Diverting Flow

These valves have three or more ports, depending on the flow diversion duty. Valves that adapt readily to this duty are plug valves and ball valves.

For this reason, most valves for the diversion of flow are one of these types. However, other types of valves have also been adapted for the diversion of flow, in some cases by combining two or more valves that are suitably interlinked.

Valves for Fluids with Solids in Suspension

If the fluid carries solids in suspension, the valves best suited for this duty have a closure mber that slides across the seat with a wiping motion. Valves in which the closure mber moves squarely on and off the seat may trap solids and are therefore suitable only for essentially clean fluids unless the seating material can bed trapped solids.

Valve End Connections

Valves maybe provided with any type of end connection used to connect piping. The most important of these for valves are threaded, flanged, and welding end connections.

Threaded end connections . These are made, as a rule, with taper or parallel fale threads, which screw over tapered male pipe threads. Because a joint made up in this way contains large leakage passages, a sealant or filler is used to close the leakage passages. If the construction material of the valve body is weldable, screwed joints may also be seal welded. If the mating parts of the joint are made of different but weldable materials with widely differing coefficients of expansion, and if the oper- ating tperature cycles within wide limits, seal welding the screwed joint may be necessary.

Valves with threaded ends are primarily used in sizes up to DN 50 (NPS 2). As the size of the valve increases, installing and sealing the joint become rapidly more difficult. Threaded end valves are available, though, in sizes up to DN 150 (NPS 6).

To facilitate the erection and roval of threaded end valves, couplings are used at appropriate points in the piping syst. Couplings up to DN 50 (NPS 1) consist of unions in which a parallel thread nut draws two coupling halves together. Larger couplings are flanged.

Codes may restrict the use of threaded end valves, depending on application.

Flanged end connections. These permit valves to be easily installed and roved from the pipeline. However, flanged valves are bulkier than threaded end valves and correspondingly dearer. Because flanged joints are tightened by a number of bolts, which individually require less tighten- ing torque than a corresponding screwed joint, they can be adapted for all sizes and pressures. At tperatures above 350。C (660。F), however, creep relaxation of the bolts, gasket, and flanges can, in time, noticeably lower the bolt load. Highly stressed flanged joints can develop leakage probls at these tperatures.

Flange standards may offer a variety of flange face designs and also recommend the appropriate flange face finish. As a rule, a serrated flange face finish gives good results for soft gaskets. Metallic gaskets require a finer flange finish for best results. Chapter 2 discusses the design of gaskets.

Welding end connections. These are suitable for all pressures and t- peratures, and are considerably more reliable at elevated tperatures and other severe applications than flanged connections. However, roval and re-erection of welding end valves is more difficult. The use of welding end valves is therefore normally restricted to applications in which the valve is expected to operate reliably for long periods, or applications which are critical or which involve high tperatures.

Welding end valves up to DN 50 (NPS 2) are usually provided with welding sockets, which receive plain end pipes. Because socket weld joints form a crevice between socket and pipe, there is the possibility of crevice corrosion with some fluids. Also, pipe vibrations can fatigue the joint. Therefore, codes may restrict the use of welding sockets.

Standards Pertaining to Valve Ends

Appendix C provides a list of the most important U.S. and British standards pertaining to valve ends.

Valve Ratings

The rating of valves defines the pressure-tperature relationship within which the valve maybe operated. The responsibility for determining valve ratings has been left over the years largely to the individual manufacturer. The frequent U.S. practice of stating the pressure rating of general purpose valves in terms of WOG (water, oil, gas) and WSP (wet steam pressure) is a carryover from the days when water, oil, gas, and wet steam were the substances generally carried in piping systs. The WOGrating refers to the room-tperature rating, while the WSP rating is usually the high tperature rating. When both a high and a low tperature rating is given, it is generally understood that a straight-line pressure-tperature relationship exists between the two points.

Some U.S. and British standards on flanged valves set ratings that equal the standard flange rating. Both groups of standards specify also the per- missible construction material for the pressure-containing valve parts. The rating of welding end valves corresponds frequently to the rating of flanged valves. However, standards may permit welding end valves to be designed to special ratings that meet the actual operating conditions.36 If the valve contains components made of polymeric materials, the pressure- tperature relationship is limited, as determined by the properties of the polymeric material. Some standards for valves containing such materials as ball valves specify pressure-tperature limits for the valve. Where such standards do not exist, it is the manufacturer’s responsibility to state the pressure and tperature limitations of the valve.

Valve Selection Chart

The valve selection chart shown in Table 3-1 is based on the foregoing guidelines and may be used to select the valve for a given flow-regulating duty. The construction material of the valve is determined on one hand by the operating pressure and tperature in conjunction with the appli- cable valve standard, and on the other hand by the properties of the fluid, such as its corrosive and erosive properties. The selection of the seating material is discussed in Chapter 2. The best approach is to con- sult the valve manufacturer’s catalog, which usually states the standard construction material for the valve for given operating conditions. However, it is the purchaser’s responsibility to ensure that the construction material of the valve is compatible with the fluid to be handled by the valve.

If the cost of the valve initially selected is too high for the purpose of the valve, the suitability of other types of valves must be investigated. Sometimes a compromise has to be made.

This selection procedure requires knowledge of the available valve types and their variations, and possibly knowledge of the available valve standards. This information is given in the following sections.

Table 3-1

Valve Valve Selection Chart

| Valve | Mode of Flow Regulation | Fluid | |||||||

| Group | Type | On-Off | Throttling | Diverting | Free of solids | Solids in Suspension | Sticky | Sanitary | |

| non-abrasive | abrasive | ||||||||

| Closing down | Globe: | ||||||||

| –straight pattern | Yes | Yes | Yes | ||||||

| –angle pattern | Yes | Yes | Yes | special | special | ||||

| –oblique pattern | Yes | Yes | Yes | special | |||||

| –multiport pattern | Yes | Yes | |||||||

| Piston | Yes | Yes | Yes | Yes | special | ||||

| Sliding | Parallel gate: | ||||||||

| –conventional | Yes | Yes | |||||||

| –conduit gate | Yes | Yes | Yes | Yes | |||||

| –knife gate | Yes | special | Yes | Yes | Yes | ||||

| Wedge gate: | |||||||||

| –with bottom cavity | Yes | Yes | |||||||

| –without bottom cavity (rubber seated) Plug: | Yes | moderate | Yes | Yes | |||||

| Rotating | Plug: | ||||||||

| –non-lubricated | Yes | moderate | Yes | Yes | Yes | Yes | |||

| –lubricated | Yes | Yes | Yes | Yes | Yes | ||||

| –eccentric plug | Yes | moderate | Yes | Yes | Yes | ||||

| –lift plug | Yes | Yes | Yes | Yes | Yes | ||||

| Ball | Yes | Yes | Yes | Yes | Yes | ||||

| Butterfly | Yes | Yes | special | Yes | Yes | Yes | |||

| Flexing | Pinch | Yes | Yes | special | Yes | Yes | Yes | Yes | Yes |

| Diaphragm: | |||||||||

| –weir type | Yes | Yes | Yes | Yes | Yes | Yes | |||

| –straight-through | Yes | moderate | Yes | Yes | Yes | Yes | |||